Frik•Shun - "The force that resists the sliding or rolling motion of one object over another"

It's what slows everything down

“Friction is like a piggy-bank. There’s pennies, nickels, dimes and quarters. And the few that ever look at it, start with the quarters. That makes my job much easier”

Mark Peiser, Crew Chief for Antron Brown/NHRA PS Bike

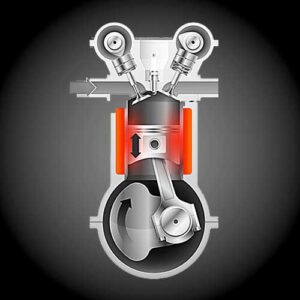

And it’s everywhere. Pistons, rings, cylinders, gears and bearings. They all play a role and they all add up. So we start with the pennies and don’t miss a thing.

In case you’re interested, that drive chain may be the biggest source of friction in your bike.

AF/1®: The only coating that reduces friction on every moving part

Developed by Stanford University for NASA in 1962, it was used in the Mariner space missions on all moving parts where lubricants couldn’t be used. It did reduce friction and wear, allowing them to successfully complete the missions.

But NASA’s application method left a lot to be desired, so we set out to design our own system and were issued a patent for AF/1® in 2006.

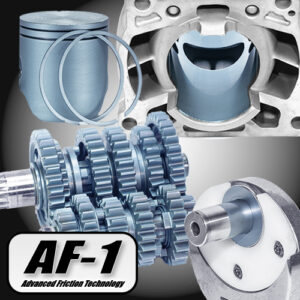

Early work focused on gears and bearings, but the whole world changed when we went to work on Eli Tomac’s pistons, rings and cylinders.

Step 1: Smoother is better

Known as isotropic surface finishing, it’s a chemical/mechanical process that smooths machined surfaces and by itself, reduces the chance of surface contact.

However, it’s impact on friction is minimal, because the real friction comes from the effort to “push” the oil from between the gear teeth.

But when combined with AF/1® (the ONLY coating that changes the way lubricants work) things get real interesting in a hurry.

Step 2: Erase 25% of the friction

The top-end is responsible for 50% of the friction. The crankshaft, gears and bearings make up the rest. And that’s why they get special attention.

So how do we do that? We know that REM finishing the gear and bearing surfaces and then coating with AF/1®, we can easily cut that friction by 25%, just let that sink in for a minute.

How much more power can we make when we remove 25% of the friction of everything that moves? And basically eliminated wear in the process?

AF/1® ceramic bearings: The finishing touch!

It’s all in the details. When it comes to racing, you’re either there to win, or there for a fashion show. If you’re there to win, and you can make something better, why wouldn’t you?

By simply coating a standard steel ball bearing with AF/1®, we reduce the friction by 25%. It is now on par with a common ceramic bearing.

When we coat a St. Gobain® ceramic ball bearing with AF/1®, the total friction is reduced by 50%. It’s a detail we never miss.

What does this mean for you?

It means that you will have the freest moving, longest lasting and most efficient engine ever created.

“My son’s an up & comer so naturally, I want him to have the best (we can afford). He races in the 85 LTD class and this bike’s a winner, thanks!”

Bill Greely – CA

Engine Development / Dyno Tuning: Rutherfordton, NC (828) 705-6013

Service & Repair: Cairo, GA (828) 748-4403

[email protected]